MRP glossary TOP > Order Receipt/Shipping Control > Lead Time

Lead Time

Lead Time, Lead Time

It is a period ranging from issuing an order to completing it. It is usually expressed by days.

The general types of Lead Time are as follows:

*Paper Lead Time

*Purchased Lead Time

*Manufacturing Lead Time

*Subcontract Lead Time

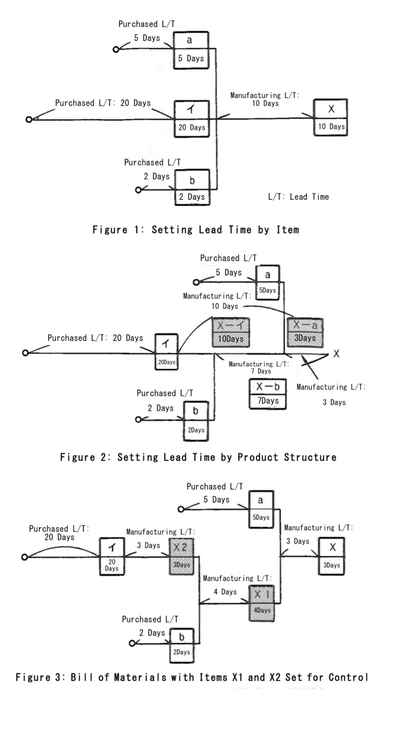

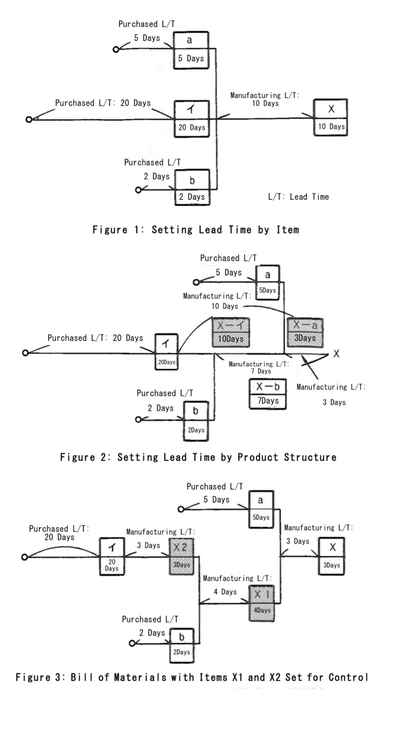

Lead time is registered in B/M. In this case, the meaning of lead time considerably varies depending on whether it is set to each item or set to the product structure. In most manufacturing companies, the material planning is performed, assuming that all the lower-level items are prepared at the time of producing the upper-level item. In this case, as shown in the figure 1, lead time is set to each item.

On the other hand, In the manufacturing companies handling larger or special products like ships, or in the case where the lead time of manufacturing or assembling is very long, as the figure 2 shows, lead time is set to the product structure showing the relationships among items. By setting lead time in such ways, the inventory time of parts and materials can be reduced, and more detailed planning of manufacturing and assembling can be performed. But common manufacturing companies have to pay attention to such considerations very little. In light of the length of lead time, much concern are not be necessary. When the lead time is too long, as depicted in the figure 3, it is common to set an administrative item in between. Using lead time set in this way, the planned release date of order is calculated.

Related term: Calculating Lead Time

It is a period ranging from issuing an order to completing it. It is usually expressed by days.

The general types of Lead Time are as follows:

*Paper Lead Time

*Purchased Lead Time

*Manufacturing Lead Time

*Subcontract Lead Time

Lead time is registered in B/M. In this case, the meaning of lead time considerably varies depending on whether it is set to each item or set to the product structure. In most manufacturing companies, the material planning is performed, assuming that all the lower-level items are prepared at the time of producing the upper-level item. In this case, as shown in the figure 1, lead time is set to each item.

On the other hand, In the manufacturing companies handling larger or special products like ships, or in the case where the lead time of manufacturing or assembling is very long, as the figure 2 shows, lead time is set to the product structure showing the relationships among items. By setting lead time in such ways, the inventory time of parts and materials can be reduced, and more detailed planning of manufacturing and assembling can be performed. But common manufacturing companies have to pay attention to such considerations very little. In light of the length of lead time, much concern are not be necessary. When the lead time is too long, as depicted in the figure 3, it is common to set an administrative item in between. Using lead time set in this way, the planned release date of order is calculated.

Related term: Calculating Lead Time

Reference:JIT Business Research Mr. Hirano Hiroyuki