MRP glossary TOP > L > Lot Sizing

Lot Sizing

Lot Sizing

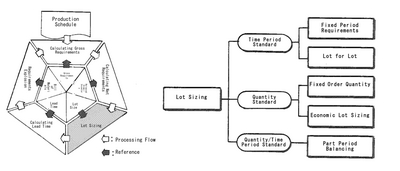

Base on the requirements of product, MRP refers to the net requirements of parts or materials. But these requirements without any change may be unsuitable for placing an order or manufacturing. Lot sizing is to unify the calculated net requirements by a certain unit considering cost reduction and work efficiency.

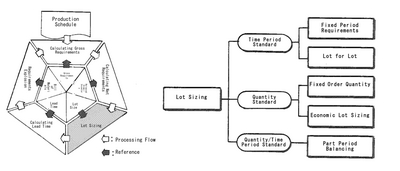

There are two main types of lot sizing: a method to unify in terms of the period and another method to unify in terms of the quantity. The former includes "Fixed Period Requirements", which, generally speaking, is suitable for the relatively expensive items whose demand occurs irregularly. The latter includes "Fixed Period Requirements" or "Economic Lot Sizing", which is suitable for items whose demand is relatively stable. In addition to these types, there are any other types of lot sizing as shown in the figure.

There are two main types of lot sizing: a method to unify in terms of the period and another method to unify in terms of the quantity. The former includes "Fixed Period Requirements", which, generally speaking, is suitable for the relatively expensive items whose demand occurs irregularly. The latter includes "Fixed Period Requirements" or "Economic Lot Sizing", which is suitable for items whose demand is relatively stable. In addition to these types, there are any other types of lot sizing as shown in the figure.

Related term: MRP

Base on the requirements of product, MRP refers to the net requirements of parts or materials. But these requirements without any change may be unsuitable for placing an order or manufacturing. Lot sizing is to unify the calculated net requirements by a certain unit considering cost reduction and work efficiency.

There are two main types of lot sizing: a method to unify in terms of the period and another method to unify in terms of the quantity. The former includes "Fixed Period Requirements", which, generally speaking, is suitable for the relatively expensive items whose demand occurs irregularly. The latter includes "Fixed Period Requirements" or "Economic Lot Sizing", which is suitable for items whose demand is relatively stable. In addition to these types, there are any other types of lot sizing as shown in the figure.

There are two main types of lot sizing: a method to unify in terms of the period and another method to unify in terms of the quantity. The former includes "Fixed Period Requirements", which, generally speaking, is suitable for the relatively expensive items whose demand occurs irregularly. The latter includes "Fixed Period Requirements" or "Economic Lot Sizing", which is suitable for items whose demand is relatively stable. In addition to these types, there are any other types of lot sizing as shown in the figure.

Related term: MRP

Reference:JIT Business Research Mr. Hirano Hiroyuki

Lot Size | L | Lot Sizing