MRP glossary TOP > L > Loading

Loading

Loading

Related term: Capacity Requirements Planning CRP

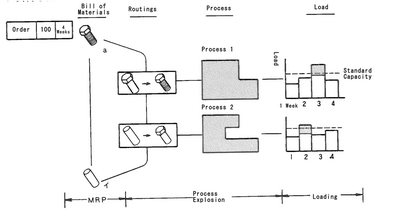

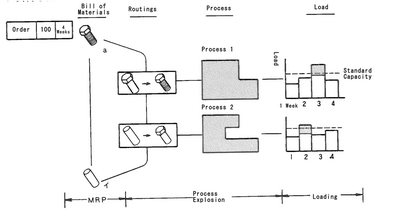

A load means the quantity of work, and allocating the quantity of work to the processes necessary to manufacture each item is called loading.

It is performed in the CRP (Capacity Requirements Planning) of the manufacturing planning. Each item planned in MRP is first explored to the processes necessary to manufacture it, which is usually called process explosion. Next loading is performed for the explored process. In loading, each load is usually piled up by time (hour), by which a setup time and a real operating time are determined. The real operating time may be set by manufacturing lot or by real operating time per item unit. In the former case, the time of hour is piled up as load, while in the latter case, loading is performed after calculating the real operating time per manufacturing unit by multiplying the number of manufacturing items by real operating time.

In addition, the calculated load is piled up for a certain period, which is determined by selecting either the earliest start date or the last start date as a base date. This method enables loading for each process or each period.

Related term: Capacity Requirements Planning CRP

Reference:JIT Business Research Mr. Hirano Hiroyuki