MRP glossary TOP > R > Rough-cut Capacity Planning RCP

Rough-cut Capacity Planning RCP

Rough-cut Capacity Planning RCP

It is usually called RCP for short, and is a plan to check the validity of factory production capacity in light of the production plan. It is used in both make-to-stock production and make-to-order one. In this planning, whether the capacity meets the load quantity of each important process or not is considered and planned by identifying the bottleneck process in a factory based on the routings and exploring it to each process.

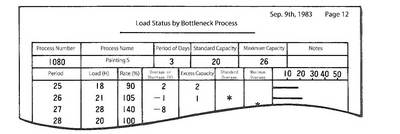

Using this plan, the production plan and its capacity are reviewed, and the resaults are taken over to MRP (in case of make-to-stock production), or the final assembling planning (in case of make-to-order production). The load status list by bottleneck process is usually created through Rough-cut Capacity Planning.

It is usually called RCP for short, and is a plan to check the validity of factory production capacity in light of the production plan. It is used in both make-to-stock production and make-to-order one. In this planning, whether the capacity meets the load quantity of each important process or not is considered and planned by identifying the bottleneck process in a factory based on the routings and exploring it to each process.

Using this plan, the production plan and its capacity are reviewed, and the resaults are taken over to MRP (in case of make-to-stock production), or the final assembling planning (in case of make-to-order production). The load status list by bottleneck process is usually created through Rough-cut Capacity Planning.

Reference:JIT Business Research Mr. Hirano Hiroyuki