MRP glossary TOP > U > Unscheduled Receive/Issue

Unscheduled Receive/Issue

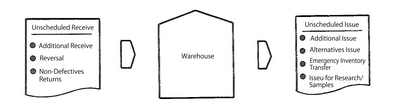

The receiving/issuing based on the order planned by MRP refers to Scheduled Receive/Issue, and others are called Unscheduled Receive/Issue . Unscheduled Receive/Issue are as follows:

Antonyms: Scheduled Receive/Issue

- [Unscheduled Receive]

- * Additional Entering:

More than the planned requirements are put into a warehouse due to less defective goods in manufacturing/subcontract orders than the initial anticipation. - * Reversal:

The items which were already dispatched to each process put back to the warehouse due to high predicted Failure Rate or urgent change in engineering. - * Non-Defectives Returns:

Non-defective goods are put back to the warehouse deu to the wrong order or wrong quantities of service parts. - [Unscheduled Issue]

- * Additional Issuing:

Since more defectives of the items which were already dispatched according to the plan order than the forecast are found, or more requirements are demanded due to the change in the manufacturing order, the necessary goods are dispatched to supplement the shortage.

while it is called "Unscheduled Inventory Transfer" or "Emergency Inventory Transfer" to perform Inventory Transfer without scheduling it. - * Alternatives Issuing:

When the shortage in the planned items occurs or the change in engineering is made before the inventory of old items is used up, the alternative items are dispatched instead of the planned items. - * Emergency Inventory Transfer:

The transfer of inventory is urgently demanded because it cannot be included in the plan. - "Unscheduled Inventory Transfer" or * Issuing for Research/Sample:

Some inventory is dispatched to the engineering division for its research or as samplings.

Antonyms: Scheduled Receive/Issue

Reference:JIT Business Research Mr. Hirano Hiroyuki