MRP glossary TOP > Material Planning > Order Status

Order Status

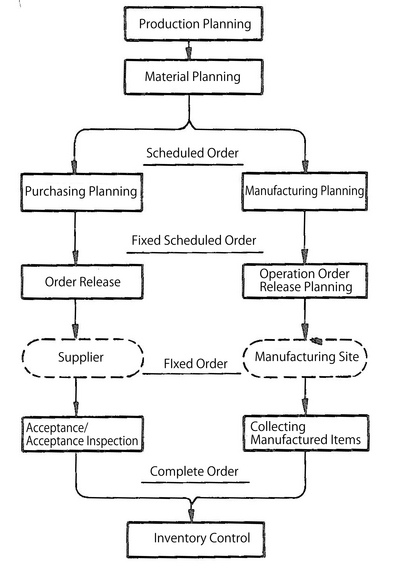

Order Status is mainly divided into Schedule, Fixed Schedule, Fixed, and Complete Schedule, and each is set according to the severity of change.

- Schedule Order:

- Based on the production plan, MRP makes a plan of assemblies, parts, and raw materials for a long period (several months). The status of all orders made at this point is "Schedule", which means even if any changes are made without any approvals due to some change in the plan, no influence is made.

- Fixed Schedule Order:

- Regarding short-term (about one month later) orders among the scheduled orders made by MRP, for manufacturing orders, the capacity planning by process is performed as part of manufacturing process control, while for purchasing or subcontract orders, the setting of suppliers and cost unit is performed as part of purchasing control. At this point, the status of order changes from Schedule to Scheduled, namely "Fixed Schedule". Fixed Schedule Orders are very reliable and if any change occurs, some influence is made on the suppliers and processes.

- Fixed Order:

- The Fixed Schedule Order is turned into Issued, namely "Fixed" through actual order placing or work instructions. Some change made at this point has severe influence on the suppliers and the sites. Therefore, as a rule, the change of Fixed Order is not acceptable, and even if accepted, quite large penalty would be paid.

- Complete Order:

- The status of the order which is done through inspection or manufacturing performance acquisition turns from Fixed to "Complete". The Complete Order is regarded as its role done, deleted, and reflected in the inventory.

Reference:JIT Business Research Mr. Hirano Hiroyuki

Order Relationship | Material Planning | Order Timing Damper