MRP glossary TOP > Material Planning > Fixed Period Requirements

Fixed Period Requirements

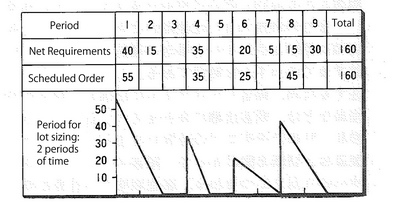

It is called FPR for short, and is a method for lot sizing, where an order quantity is obtained by fixing the quantity of period for lot sizing of each item, and calculating the total quantity of Net Requirements within the period. This is usually a common method due to easy setting of the standard level for lot sizing and reduced frequency of setup replacement and placing orders. Due to the change in quantity, however, some coordination with the capacities may be required. When no Net Requirements occur at the beginning of the sizing period (Period 3 in the figure), the sizing is performed by skipping the period and regarding the next period as the beginning.

Related term: Lot Sizing,LFL

Reference:JIT Business Research Mr. Hirano Hiroyuki