MRP glossary TOP > Production Planning > Job Order Production

Job Order Production

Job Order Production

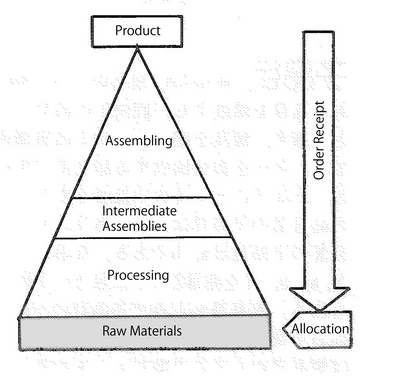

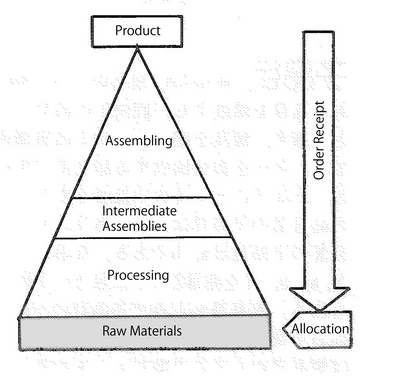

Thinking of production scheme from the standpoint of the one to be provided, it is a method to produce products by receiving individual orders from customers, deciding the specifications, and performing necessary logistics, where very few allocations to products or parts are performed. This scheme is often used when products are individually produced by make-to-order production system, which takes a high-mix low-volume manufacturing form. In this case, it is difficult to maintain the order status stable and the high variation in operation capacity is observed. Therefore it is required not only to stabilize the order quantity, automate the engineering, and standardize the parts, but also to improve the factory operating rate by focusing on the progress management of receiving orders and comprehensive delivery-date management.

Related term: Production System

Thinking of production scheme from the standpoint of the one to be provided, it is a method to produce products by receiving individual orders from customers, deciding the specifications, and performing necessary logistics, where very few allocations to products or parts are performed. This scheme is often used when products are individually produced by make-to-order production system, which takes a high-mix low-volume manufacturing form. In this case, it is difficult to maintain the order status stable and the high variation in operation capacity is observed. Therefore it is required not only to stabilize the order quantity, automate the engineering, and standardize the parts, but also to improve the factory operating rate by focusing on the progress management of receiving orders and comprehensive delivery-date management.

Related term: Production System

Reference:JIT Business Research Mr. Hirano Hiroyuki