MRP glossary TOP > Production Planning > Resource Requirements Planning RRP

Resource Requirements Planning RRP

Resource Requirements Planning RRP

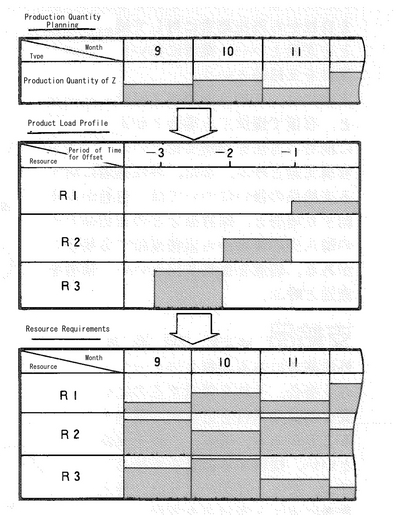

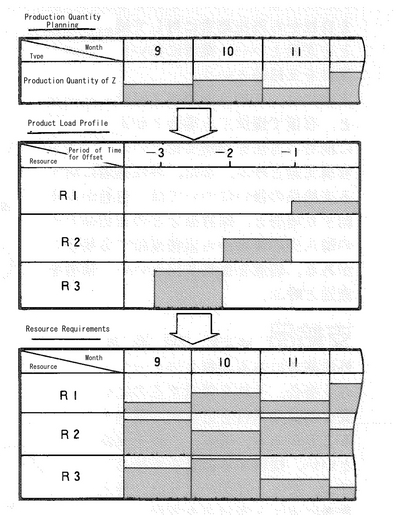

It is also called RRP for short, and is to plan the requirements of productive resources including machine/equipment, workers, fund based on the Production Plan. Specifically speaking, it is to calculate the requirements of each resource by period, referring to the product load profile, based on the planned production by month. Using this Resource Requirements Planning, the production plan, capacity plan, and financial plan are reviewed. In the figure, the Production Plan of Z is scheduled to be performed every month starting from September, and the Production Plan of each month expresses the load to necessary resources obtained from the product Z load profile. For example, the load to each resource caused by Z's November production is displayed in Resource R1's November, Resource R2's October, and Resource R3's September in the product load profile.

Related term: Make to Stock Plan (in a broad sense)

It is also called RRP for short, and is to plan the requirements of productive resources including machine/equipment, workers, fund based on the Production Plan. Specifically speaking, it is to calculate the requirements of each resource by period, referring to the product load profile, based on the planned production by month. Using this Resource Requirements Planning, the production plan, capacity plan, and financial plan are reviewed. In the figure, the Production Plan of Z is scheduled to be performed every month starting from September, and the Production Plan of each month expresses the load to necessary resources obtained from the product Z load profile. For example, the load to each resource caused by Z's November production is displayed in Resource R1's November, Resource R2's October, and Resource R3's September in the product load profile.

Related term: Make to Stock Plan (in a broad sense)

Reference:JIT Business Research Mr. Hirano Hiroyuki