MRP glossary TOP > Production Planning > Parts Oriented Production System

Parts Oriented Production System

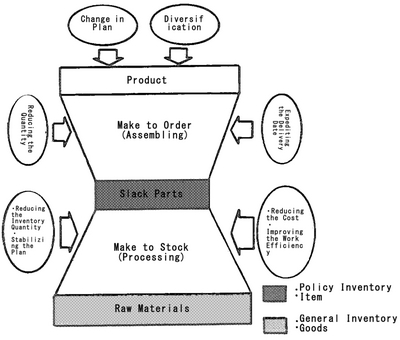

Thinking of production system in terms of allocation target, the system is called Parts Oriented Production System. In this system, standard parts and units are produced in advance, and these items are provided to the orders from customers. In this case, a wide variety of orders can be handled by combining these items with each other. The standard items which are produced in advance are called slack parts or intermediate stock goods, which are handled as policy inventory items. The parts, as shown in the figure, are produced according to the anticipation based on the demand forecast, and the production from slack parts to products are performed according to actual job order. In other words, the Parts Oriented Production System is a complex production system where make-to-stock (before slack parts) and make-to-order (after slack parts) are coexisting. In this production system, the diversification of products and quicker delivery can be handled by setting the position of the slack parts, and the reduction of inventory is also possible by using the product allocation scheme. It is also important in this system to standardize the slack parts, keep the number of items to be controlled as few as possible, improve the accuracy of demand forecast in the slack parts. MRP is mainly used in the material planning of "make to stock" at the lower level than slack parts.

Related term: Production System

Reference:JIT Business Research Mr. Hirano Hiroyuki

Paper Lead Time | Production Planning | Parts Stock Production