MRP glossary TOP > Engineering Data Control > Engineering Change

Engineering Change

It is usually called EC for short, and is performed due to the following:

- Improving products:

- The function of products is reviewed and its materials are changed to reduce their cost through value engineering activities.

- Improving technical skills:

- Items which have traditionally been set may be unnecessary due to the improvement in manufacturing procedure and facilities.

- Ensuring safety:

- Some product failure occur, and thus the engineering is changed for safety reason, whose change is usually made rapidly.

- Correcting the errors in bills of materials:

- The registered bills of materials may have engineering errors and inputting errors, which are quickly needed to be corrected.

The ones to be changed are mainly classified into two types: the item contents themselves and product structure such as physical unit. Such changes occurs mainly by the engineering division, and the demands from the production technology division, purchasing division, and other divisions may require the change in engineering. Engineering change meetings are held to grasp the influence and determine the time for the change. In the engineering and producing gechnology divisions, what products the parts change has influence on is examined, and the explicit range of influence is grasped, while in the purchasing and manufacturing divisions, the status of released orders or inventory is grasped and the changing time is determined so that the cost would be minimized. Regarding the time for the change, the point is generally determined by the following four methods:

- Instant change:

- When the changes (e.g. the change in defective parts) are related to safety, it is done instantly.

- Change after all stocks are consumed:

- After the current inventory goods are all consumed, some changes are made.

- Specifying the date:

- The time for the change is specified by the date. In this case, the available period of items, e.g. "from when (start)" and "to when (end)" is usually shown.

- Specifying the serial number:

- By specifying the serial number of product, e.g. "from what number (start)" and "to what number (end)", the Serial Number of available products are shown.

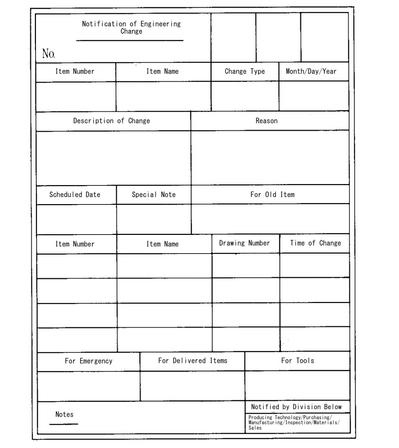

When some engineering changes are performed, an engineering change report like the one shown in the figure is distributed to ensure the confirmation and cooperation among divisions.

Reference:JIT Business Research Mr. Hirano Hiroyuki

Engineering Bill of Materials | Engineering Data Control | Engineering Change Number